Crush Testing – Compressive Strength Testing

The United Scanning team know a lot about concrete. Over the years we have worked on bridges, multi-story car parks, heritage building footings, concrete pressurised gas domes and hospitals to give just a few examples. We were responsible for one of the most detailed concrete scanning jobs in the world according to the Geophysical Archaeometry Laboratory in the US.

One common question our customers ask us about concrete, and particularly, the concrete in their building or structure is, “How strong is it?” Sometimes they have an older structure and wish to know the effect time and decay has had upon the strength of the structure. Sometimes they wish to repurpose or alter the use of an existing concrete slab or footing and want to be confident the concrete can carry the new load. Customers with new buildings and structures often require confirmation that the concrete conforms to the strength requirements they originally established with their building contractor.

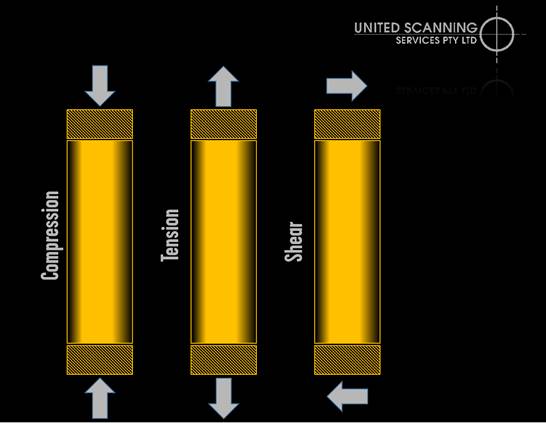

A crush test (more accurately a compressive strength test) is the way United Scanning usually answers this question. The compressive strength of a material, in this case concrete, is the ability of the material withstand or carry loads that would tend to compress it.

Figure 1: Different types of load

United Scanning acquire a core sample of the concrete from the customer site and send this to our NATA (National Association of Testing Authorities) accredited laboratory to be tested according to the Australian standard (AS 1012.9:2014 – Methods of testing concrete – Compressive strength tests – Concrete, mortar and grout specimens).

To acquire a sample to crush test, United Scanning work with the customer to select an area or areas of concrete that best represent the condition of the concrete as a whole or the condition of the concrete that needs testing. Having decided the general areas that will provide the concrete samples, United Scanning then scan the area using Ground Penetrating Radar to locate the steel reinforcing in that area. This way, the core sample can be taken in such a way as to miss the reinforcing and have least effect on the overall strength of the concrete structure.

Figure 2: Core drilling to acquire sample with a 75mm barrel.

Figure 2: Core drilling to acquire sample with a 75mm barrel.

Figure 2.1: Core drilling to acquire sample with a 40mm barrel.

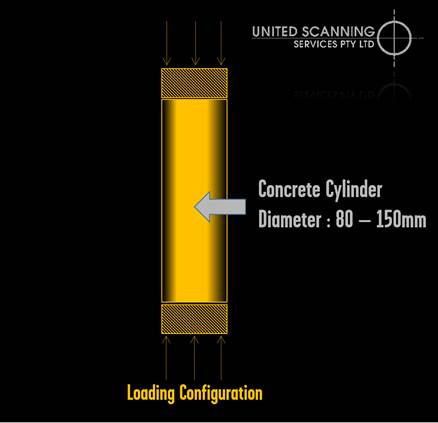

Usually, core samples are taken using an 80mm to 100mm barrel, with greater diameter samples providing more reliable crush test results. However, because customer rarely want a large hole in their concrete, a compromise is struck between our wish for a larger more reliable sample and the clients wish for a smaller hole.

Once the sample is at the lab for testing, the lab will square the ends of the sample if they are not already square and then perform the test, using a specialized machine that applies and measure compressive stress or load.

Figure 3: Crush Test diagram

The test involves placing a steadily increasing load down the length of the core sample (1.) until the sample fractures and breaks (2.). The load at which the concrete collapses indicates its compressive strength, and from this can be calculated an array of useful information.

Figure 4: Crush Test sample being compressed

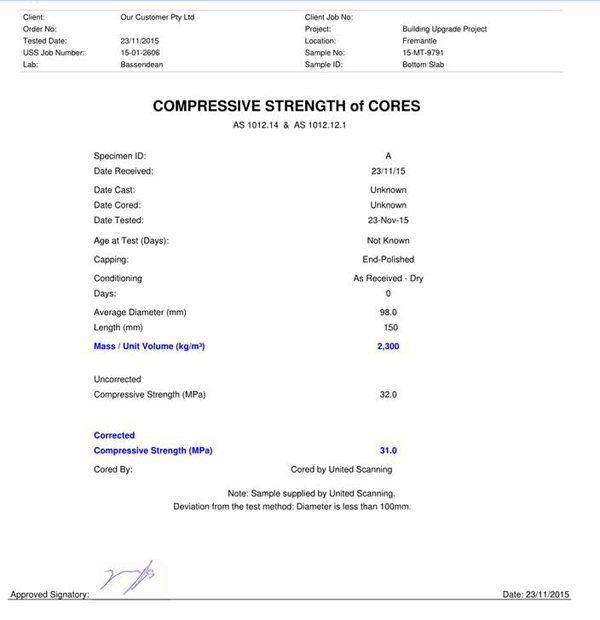

Our NATA accredited laboratory will then provide a report of the outcome of the crush test which United Scanning forward on the customer, along with our detailed description of the work performed for the customer to achieve their aim.

Figure 5: Example of Compressive Strength Test report